ALBOX GETS READY TO MAKE SOUND IN THE WORLD.

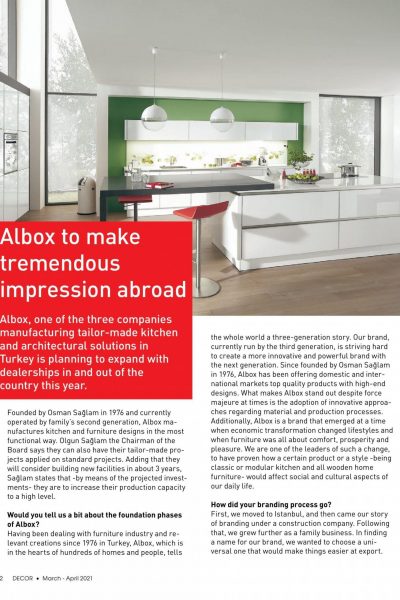

Albox, one of the three companies Albox to make tremendous impression abroad manufacturing tailor-made kitchen and architectural Solutions in Turkey is planning to expand with dealerships in and out of the country this year.

Founded by Osman Sağlam in 1976 and currently operated by family's second generation, Albox manufactures kitchen and furniture designs in the most functional way. Olgun Sağlam the Chairman of the Board says they can also have their tailor-made projects applied on Standard projects. Adding that they will consider building new facilities in about 3 years, Sağlam States that -by means of the projected investments- they are to increase their production capacity to a high level. the vvhole vvorld a three-generation story. Our brand, currently run by the third generation, is striving hard to create a more innovative and povverful brand with the next generation. Since founded by Osman Sağlam in 1976, Albox has been offering domestic and international markets top quality products with high-end designs. What makes Albox stand out despite force majeure at times is the adoption of innovative approaches regarding materialand production processes. Additionally, Albox is a brand that emerged at a time when economic transformation changed lifestyles and when furniture was ali about comfort, prosperity and pleasure. We are one of the leaders of such a change, to have proven how a certain product or a style -being classic or modular kitchen and ali vvooden home furniture- would affect social and cultural aspects of our daily life.

> Would you teli us a bit about the foundation phases of Albox?

Having been dealing vvith furniture industry and relevant creations since 1976 in Turkey, Albox, vvhich is in the hearts of hundreds of homes and people, telis How did your branding process go?

First, we moved to İstanbul, and then came our story of branding under a construction company. Follovving that, vve grew further as a family business. İn finding a name for our brand, we wanted to choose a universal one that vvould make things easier at export.

As a result, we brought the vvords al', meaning red' and 'box' together and the corporate name 'Albox' emerged. The starting point of the idea was to enliven spaces with colors. VVhile our brand was emerging more professionally, different departments had to be built. I took över the managerial position. My brother Fatih Sağlam runs ali the organization related to production as the production manager. My other brother, Zikrullah Sağlam is in charge of ali the planning vvithin the organization and Emre Sağlam deals with brand management. We were a manufacturing company for long; then, came the idea of bettering our business. We opened a store in 2010. İn 2011, we received a dealership offer to represent an international brand and we accepted it. We had been the representative of that brand for about 4 years. During the time of dealership, we bettered ourselves in many ways in terms of product development and design. The expertise we obtained contributed greatly to the development of Albox brand. Foltowing alt those steps, we started to produce high-end products. We believe we have done the right thing and pressed the right buttons.

> That's how we successfully built our brand. How about Solutions you offer to your clients?

It's not just kitchens we manufacture. We also deal with architectural Solutions. We execute our own projects as well as projects of architectural offices. Because the conditions have changed, we have adapted to them. We have already been doing our best to implement what is technically possible. We have got functional products that can be lowered or raised according to needs. The wagon systems that come out of a cabinet, products that can rotate 360°, lids that can be opened with a simple touch, products that can be added to built-in devices, systems that let the kitchen hood move över the counter are some of the Solutions we now offer. We do have Solutions that can have a dual function, both a kitchen and an Office table.

> İn short, we offer suitable Solutions to diverse needs. Being able to export to a lot of different countries demands a solid production performance. Where does it come from?

We have two different production lines at our factory located in Atasehir, İstanbul. One is the vvorkshop we inherited from our ancestors. İn addition, we have a machinery park armed with industrial machines. Although it varies from time to time, an average of 50 employees are employed at our plant. We can produce 4000 kitchens and bathrooms and around 8000 doors annually. We plan to increase those figures in the future. We are planning to move to a new, 10 thousand sqm facility in 3 years.

> Food and its contact with outside material in the kitchen is a serious issue. İn this sense, what is it you pay particular attention to?

Antibacterial products, for example, have already been in our lives for 10 years. We use it on ali countertops. Laminate, when exposed to a Chemical, has a high rate of degradation, thus causes bacteria to form there. European manufacturers use it more than we do. To prevent it from happening, we are supposed to use the right product. Since some Chemicals may be released when they come into contact with air or vvater, what is important is to choose right products that Chemicals will not react with. As a brand, we pay close attention to such details. İn this regard, we work with reliable companies for raw material we need because they produce quality products in a careful manner.

> How would you conclude your comments?

If one counts three companies that make tailor-made production, we are one. If one is able to implement custom-made designs, it can easily handle Standard ones. We want to be renovvned as a company that manufactures according to what is personally vvished for. We are planning to up the number of our dealers to 5 by the end of 2021. They will be located in Ankara, Antalya, Bodrum, one in Black Sea region and one in Central Anatolian region. As for abroad, we want to expand our business at our main markets, Europe and American Continent. We barely display 30% of our performance there. Our objective is to raise export share of our production to 60%. March - April 2021 • DECOR 33